BOLE Injection Molding Machines Provide Micelli’s Sweet Success

Micelli Mold Co. Depends on BOLE Machinery’s injection molding machine for production of its precision chocolate molds

Stow, Ohio, May 15, 2020: Micelli Mold Co., based in West Babylon, NY, had been in business since 1917 making chocolate molds for leading chocolate companies throughout North America. For the 60 years these intricate chocolate molds were made of metal. In about 1987, the company changed over to producing the precision chocolate molds by the injection molding process.

Today, Micelli is the only company in North America that produces these high-tolerance chocolate molds supplied to 700 chocolate companies. Only nine companies in the world made chocolate molds! Making these precision chocolate molds from polycarbonate requires injection molding presses that offer a stable platen design that reduces deflection and provides longer life for the aluminum molds out of which the candy molds are made.

Tim Goddeau, co-owner of Micelli who, along with a partner, purchased Micelli Mold in 2007, said that BOLE Machinery offered the best injection molding machine for the job. Micelli was one of the first US. customers to purchase a BOLE EK series machine, and it was the unique, patented toggle design that sold Goddeau on the BOLE machine.

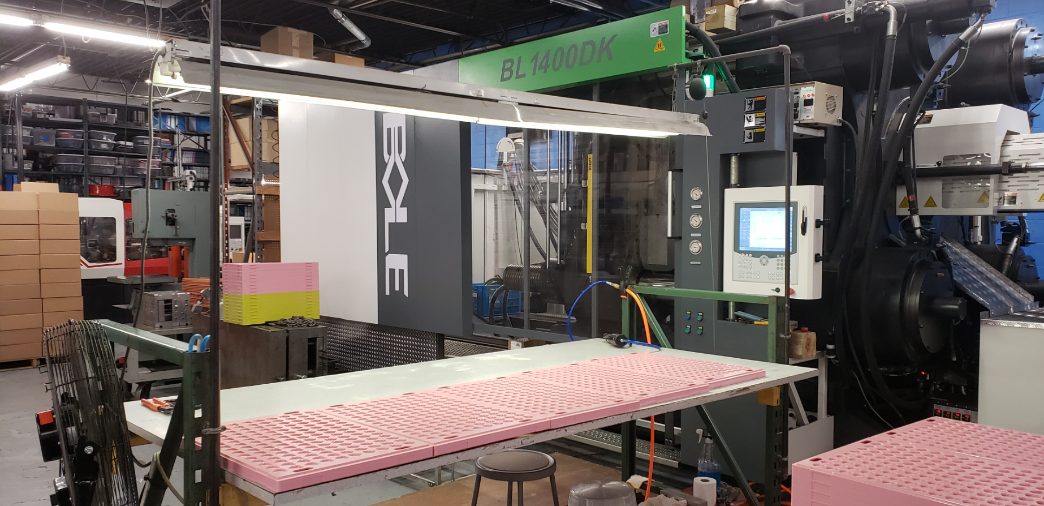

BOLE 1400DK Series Injection Molding Machine at Micelli Mold Co.

BOLE’s EKS line of injection molding machines incorporates a unique patented, German-engineered toggle linkage design known as the “Center Clamp” toggle system. Traditional toggle designs place the toggle pins near the outside edges of the platens resulting in platen deflection – the bending of the platen around the mold. This deflection causes parting line wear – something aluminum molds are particularly susceptible to experience – and can result in a poor quality chocolate mold.

“The toggle system is unique – the toggle lock is 100% horizontal and is very efficient in that there are certain jobs in which we can run less tonnage and hold the part weight accurately,” said Goddeau, adding that part weights range from one pound for the smallest chocolate mold up to eight pounds for the largest, and have wall thicknesses of .0150 in. to .0160 in., and up to 4 feet long by 1 ft. wide that can mold 244 pieces of chocolate at a time. Flatness is absolutely critical and the chocolate molds need to hold 0010 in. over 4 feet. “These are very high tolerance chocolate molds,” emphasized Goddeau. “Our customers have a system to check to make sure the tolerances on every cavity are exact within .0002 in. tolerance. A lot of the chocolate machinery is made in Europe and operates with incredibly high tolerances for the chocolate pieces.”

Micelli purchased the first BOLE machine in 2015 when Goddeau was looking to add some equipment. “I came across the BOLE machine and it was the same cost as a used machine I’d been looking at that had no warranty,” said Goddeau. “That plus the customized features of the Bole to give me exactly what I needed made the decision easy.”

BOLE 500EK Series Injection Molding Machine at Micelli Mold Co.

Micelli has been running that machine – an 800-ton press – for the past five years, six days a week, and it has proven to be ideal for the job.

“Because we do not have high-volume production we build our molds out of aluminum, and need good clamping to extend the life of these molds,” explained Goddeau. Micelli builds about 250 chocolate molds each year, most of them built for 100-200 pieces and the biggest producing 2,000 pieces of chocolate. The molds are produced in the company’s five Bole injection molding machines – including a BOLE DK two-platen machine – that range from 200 to 1400 tons.

“Our relationship with BOLE is more than just a customer and a supplier,” commented Goddeau. “We help each other. They go out of their way to help us with customizing the machines specific to the work I do. I’ve looked at several machines but I believe these are the best on the market.”

If you have any questions on this article, please reach-out and contact BOLE Machinery for more information. You can also contact our trusted Dealers for more information about obtaining BOLE injection molding machines in your vicinity

The world’s well-known brands trust BOLE

|  |  |  |  |

Copyright 2021 BOLE America

THE MANUFACTURER RESERVES THE RIGHT TO MAKE CHANGES AND/OR IMPROVEMENTS IN DESIGNS & DIMENSIONS WITHOUT PRIOR NOTICE AND WITHOUT INCURRING ANY OBLIGATION.